Infrarot-Temperaturmessung vs. NTC-Thermistoren: Welche Lösung passt wirklich zu Ihrem Design?

Oct 15, 2025„Ist berührungslose Temperaturmessung immer besser?“ Im Zeitalter intelligenter Geräte ist die Temperaturmessung zu einer zentralen Anforderung im Produktdesign geworden. Ob beim Batteriemanagement, bei Haushaltsgeräten oder bei Industrieanlagen – eine präzise Temperaturregelung hat für Ingenieure nach wie vor höchste Priorität.

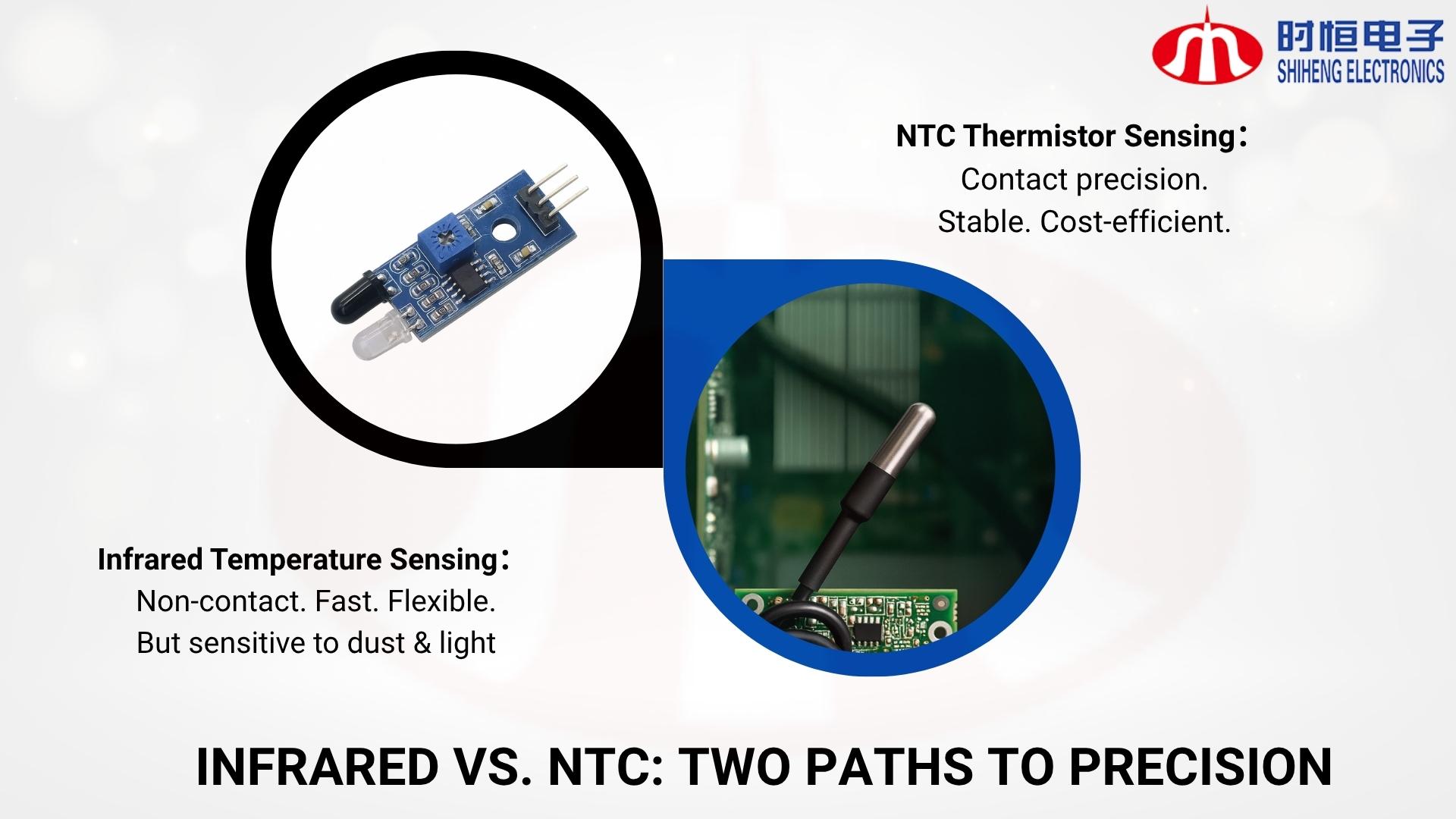

Unter den gängigen Lösungen bevorzugen einige den berührungslosen Komfort von Infrarotsensoren, während andere auf die stabile Zuverlässigkeit von NTC-ThermistorenAber was ist der wirkliche Unterschied – und wie wählt man das Richtige aus?

1. Zwei grundlegende Ansätze, die sich grundlegend unterscheiden.

|

Vergleich |

NTC-Thermistor |

Infrarotsensor |

|

Messmethode |

Kontaktbasiert, Widerstand ändert sich mit der Temperatur |

Berührungslos, erkennt Infrarotstrahlung |

|

Genauigkeit |

Hoch, ±0,1–0,5 °C, stabil über die Zeit |

Mäßig, ±1–2 °C, abhängig von der Umgebung |

|

Reaktionsgeschwindigkeit |

0,5–2 s, über das Gehäusedesign einstellbar |

Schneller, typischerweise 100–300 ms |

|

Installation |

Muss das Ziel berühren oder eng anliegen, erfordert gute Wärmeleitung |

Flexibel, benötigt freies Sichtfeld |

|

Kosten |

Niedrig, einfache Integration, skalierbar |

Höher, erfordert Optik und Kompensationsschaltungen |

|

Umweltverträglichkeit |

Hohe Beständigkeit gegen Öl, Dampf und Reflexionen |

Empfindlich gegenüber Staub, Feuchtigkeit, Rauch, Blendung |

2. Warum entscheiden sich viele Ingenieure immer noch für NTC-Thermistoren?

Trotz der Attraktivität „berührungsloser“ IR-Sensoren bleiben NTC-Thermistoren in kritischen Anwendungsfällen unersetzlich:

3. Vergleiche mit der realen Welt.

4. Den richtigen Sensor auswählen.

Fragen Sie sich:

Allgemeine Regel:

5.Shiheng Electronics – Ihr zuverlässiger Temperaturpartner.

Bei Nanjing Shiheng Electronics sind wir auf NTC-Thermistoren für verschiedene Anwendungen spezialisiert:Glasgekapselt, epoxidbeschichtete, SMD-, Sonden- und bedrahtete Designs. Anpassbare Widerstandskurven, Abmessungen und Verdrahtungsoptionen.

Bewährte Leistung in:

Suchen Sie nach der optimalen Lösung für Ihr Design? Kontaktieren Sie das Shiheng-Team für Muster, technischen Support und maßgeschneiderte Empfehlungen.